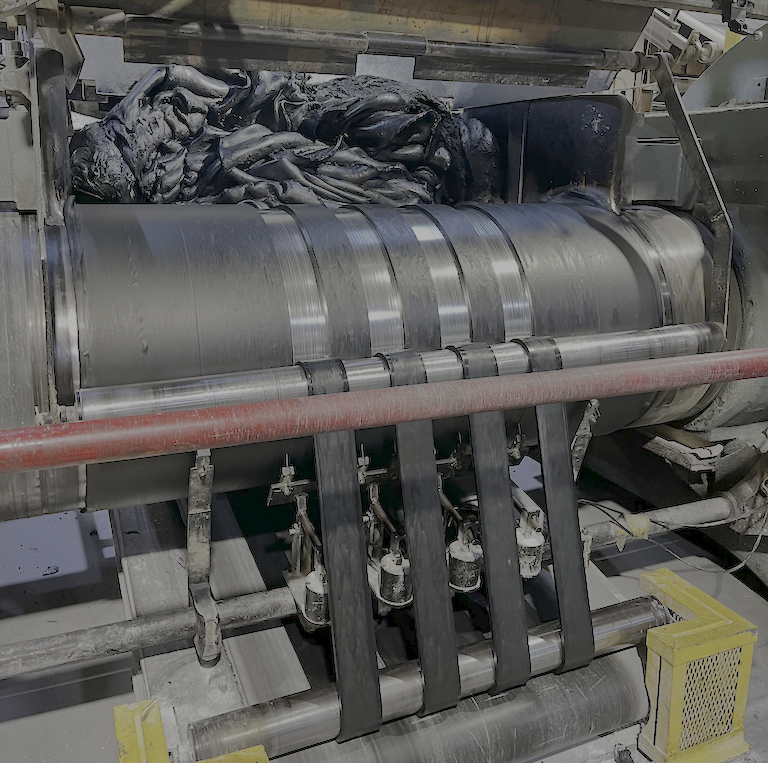

Rubber Mixing You Can Count On

Precision mixing.

Dependable quality.

On-time delivery.

Built for long-term partners.

When your compound has to run right the first time, you need a mixer who takes consistency personally. At American Phoenix, we mix rubber with tight controls, a steady process, and the kind of follow-through you only get from a team that’s been doing this for decades.

What We Do

We mix customer-specified rubber compounds using internal mixers and controlled processes. You bring the recipe/spec and performance targets—we run the batches, keep it consistent, and communicate early if anything needs attention.

- Black & non-black compound mixing

- ISO-Certified

- R&D to production

- Customer recipe to spec

- Materials: customer-supplied or managed

Consistency Doesn’t Happen by Accident

Every batch is run under defined controls to support uniform dispersion, accurate formulation, and dependable downstream performance. If something needs attention, we don’t hide it—we talk early and solve it with you.

ISO-certified operations means we do what we say we’re doing—every day.

How a Job Runs

A simple, proven flow—enough detail to understand the process, not a “sausage-making” download.

- Spec + recipe review

You share your requirements, targets, and any must-haves. - Material plan + scheduling

We align the run to your timeline and material model (customer-supplied or managed). - Mixing under controlled process

Batches are run with defined parameters and consistent checks. - Quality release

We confirm the batch meets requirements before it moves forward. - Shipment + follow-through

You get clear communication and support if you need adjustments on the next run.

Mixing Equipment

Here’s what we run. If you’re trying to match batch size, cycle time, or development work, we’ll help you map the right fit.

What this means for you: we can support everything from trial batches and development work to high-throughput production—without forcing you into a one-size-fits-all approach.

Mixing Equipment

Compounds We Mix

Lab Capabilities

Materials: Your Way, or Ours

Some customers want us to run from our inventory. Others supply their own materials. Either way works – what matters is keeping the job organized, controlled, and on schedule.

Why Choose API?

We're not trying to be flashy. We're trying to be the team you don't have to worry about.

- Built for real manufacturing schedules — planned runs, project work, or urgent needs.

- Precision you can build on — tight process control and consistent output.

- Flexible when real life hits — we communicate early and adapt when possible.

- Fair value, strong relationships — we value long-term partners as well as smaller projects.

- Technical support that’s actually helpful — clear answers, quick response, no runaround.

ISO 9001:2015

ISO 14001:2015

Frequently Asked Questions

What batch sizes can you support?

We support lab-scale and small development batches through volume production. The best fit depends on your compound, your targets, and your timing—send the details and we’ll recommend the right path.

Do you run both black and non-black compounds?

Yes. We run black and non-black mixing and take the discipline required for non-black work seriously. Tell us what you’re running and what matters most (color sensitivity, changeover expectations, etc.).

Can you work from our recipe/spec?

Yes. You provide the recipe/spec and performance requirements—we mix to spec and communicate early if we see anything that could impact results.

Can we supply our own raw materials?

Yes. Some programs run with customer-supplied materials; others use managed materials. Either way, the goal is the same: controlled, organized, and on schedule.

What's your typical lead time?

Lead time depends on material availability, batch size, and current schedule. Send your spec and timeline—we’ll give you a straight answer and an honest path forward.

Need mixing support you can trust?

Send your spec, your batch needs, and your timeline. We’ll tell you what we can do—and we’ll be straight with you if something needs a different approach.

Eau Claire, WI

Rubber Mixing & Extruding

800 Wisconsin St. #11

Eau Claire, WI 54703

Topeka, KS

Pre-Weigh Facility

7215 Topeka Blvd.,

Building 9A

Topeka, KS 66619

Fayetteville, NC

Pre-Weigh Facility

318 Blount Street

Fayetteville, NC 28301

Danville, VA

Pre-Weigh Facility

121 Martha Street

Danville, VA 24541

Lawton, OK

Pre-Weigh Facility

5201 SW 11th Street

Lawton, OK 73501

Useful Links

Contact Us

sales@apimix.net

Phone

Sales: (715) 831-0966